Description

SPIRAL FEED TYPES AND MAIN PARTS

With rabbit feeders, the best feed conversion rates are achieved from the first day of rearing to the last day of rearing. All types of Tavsan feeders have the features of easy cleaning, minimum feed loss and easy level adjustment.

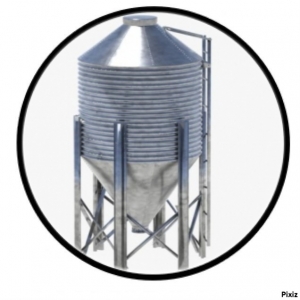

Spiral feed tanks are of 2 types, 90 kg and 170 kg, according to their feed capacities. Feed tanks with the desired capacity provide perfect feed distribution to the feeder lines.

Spiral feeding tank is also available with double outlet to be installed in the middle of the house. Over-tank sheet thickness is 1 mm, under-tank sheet thickness is 1.5 mm. The coatings are 275 gr/m2.

Spiral pipe is made of 1.2 mm thick sheet metal and galvanized 275 gr/m2. The claw on it prevents feed loss by preventing the feeders from turning.

The switch at the end of the spiral feeder line automatically stops the motor when all the feeders are full. With the decrease of the feed in the feeders, the engine automatically starts working again.

Thanks to the lock system in the feed tanks; The upper part of the tank can be easily separated from the lower part, allowing the system to rise up to the ceiling. In this way, the mangers are lifted to the maximum height and the litter is cleaned without any problems.

In order to save energy, the chicks are collected in a certain area in broiler houses, especially during the chick period, by not using the feeder line completely. During this period, thanks to the stoppers placed at the place where the chamber is located, the feed is prevented from going to the area where there are no living things, ensuring that the feed remains fresh and feed loss is prevented.

Spiral feeder system works without problems up to 150 meters.

The feeding system engine provides high performance with its special design.

TECHNICIAL SPECIFICATIONS

Maximum length of the system 150 m

Feeder pipes with 2, 3 or 4 holes

Outer diameter: 45 mm Inner diameter: 42.6 mm

Standard motor specifications 0.55 kW (0.75Hp) 220/380V 50 Hz, 3-phase, 350 rpm

Special voltage and power motors are available.

Feed carrying capacity Average 450 kg / hour

Lifting Recommended every 3 meters

Warehouse alternatives 90 kg 170 kg

Reviews

There are no reviews yet.